|

|

|

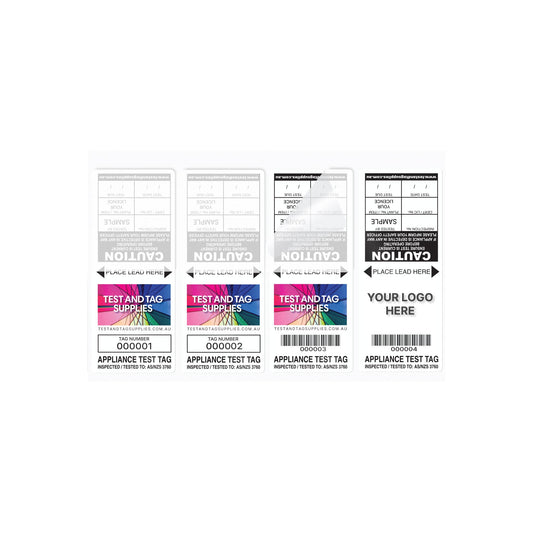

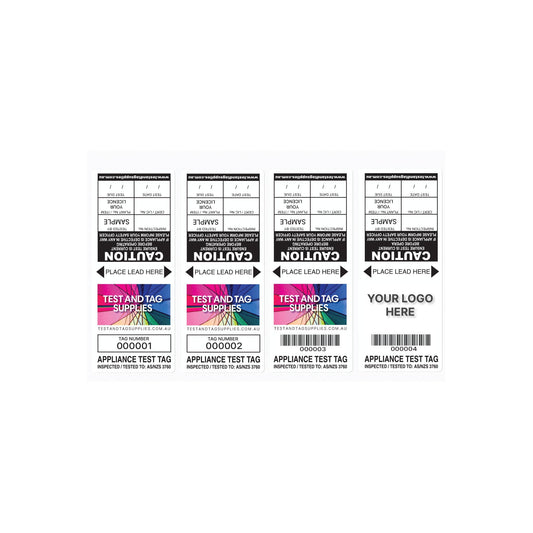

| Self Laminating Test Tags | Rainbow Test Tags | Customised Test Tags |

Many customers frequently ask us "what colour test tags should I use?"

The following colours are the recommended industry colours for test tags in Australia. These are applied depending on the required retest period and according to the test frequency. The test frequency is determined by the environment in which the appliance will be used.

Tag colours are not a legislative requirement. However, colour coding test tag colours is recommended - particularly on construction sites in Australia where colour coding of test tags maybe enforced by private businesses or organisations.

Colour coding schemes are also recommended by standards including AS/NZS 3012 Electrical installations - Construction and demolition sites.

If you need to use the 4 industry recommended colours for construction, Red, Blue, Green and Yellow, mixed packs of tags are available (see here). These are sometimes referred to as 'Rainbow' packs or the 'Rugby or RGBY' system (stands for Red, Blue, Green and Yellow). Other than the colour mix, they're generally just coloured durable tags in a mixed pack of colours!

| Red | Dec-Feb | |

| Green | Mar-May | |

| Blue | Jun-Aug | |

| Yellow | Sep-Nov | |

| Orange | Jan-Jun | |

| White | Jul-Dec | |

| Black | Yearly | |

| Burgundy | 5 Yearly |

The following colours are the former NSW recommended colours. The NSW Managing electrical risks in the workplace code of practice requires compliance with the requirements of AS/NZS 3012.

| Red | Jan & Sep | |

| Blue | Feb & Jul | |

| Orange | Mar & Nov | |

| Green | Apr & Aug | |

| White | May & Dec | |

| Yellow | Jul & Oct |